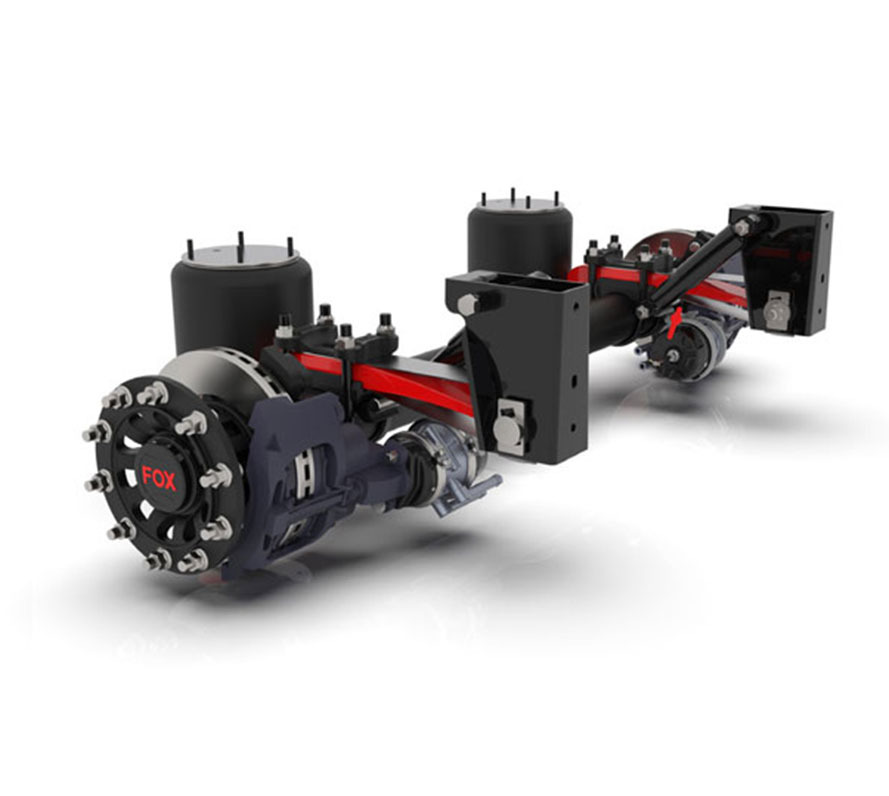

FOX Disc Brake Axle (9 ton) With Leaf Spring (100 mm): Precision, Power, and Purity of Performance

When maximum safety, structural rigidity, and optimal road adherence are required for heavy-duty trailers, compromise is not an option. Chichest is proud to feature the FOX Disc Brake Axle (9 ton) With Leaf Spring (100 mm), an assembly that merges the robust engineering of the FOX brand with precise technical specifications for the most demanding applications. This axle is specifically designed to manage a 9-ton load capacity while leveraging the reliable support and proven strength of a 100 mm wide leaf spring system.

Advantages of Using the FOX Disc Brake Axle (9 ton) With Leaf Spring (100 mm)

The specialized combination of a FOX-engineered axle, disc brakes, and the specific 100 mm leaf spring width results in a high-performance assembly with distinct competitive advantages.

1. Engineered for Excellence: The FOX Difference

The FOX brand is synonymous with high-quality, durable components in the automotive and heavy machinery sectors. When integrated into the Disc Brake Axle (9 ton), this means:

- High-Precision Machining: FOX axles are manufactured to exacting tolerances, ensuring perfect alignment and minimizing friction and wear on bearings and seals.

- Superior Materials: Use of high-grade alloy steel ensures that the axle tube and spindle can withstand continuous stress and dynamic loads far exceeding the rated 9-ton capacity.

- Corrosion Resistance: Enhanced protective coatings are applied to maximize resilience against environmental factors such as salt, moisture, and road debris, extending the service life of the entire FOX Disc Brake Axle (9 ton) With Leaf Spring (100 mm) assembly.

2. Enhanced Stability and Load Dispersion (The 100 mm Leaf Spring Advantage)

The choice of a 100 mm wide leaf spring system is a technical decision that offers measurable benefits over narrower alternatives:

- Wider Load Footprint: A 100 mm spring provides a wider contact area on the spring seat and frame mount, which significantly improves the lateral stability of the trailer, crucial when carrying a full 9-ton payload.

- Reduced Spring Stress: The wider spring distributes the load over a larger cross-section of steel, reducing the stress on individual leaves and dramatically decreasing the chance of premature spring failure.

- Improved Roll Stability: This wider base helps resist trailer roll (sway) during cornering or when encountering uneven terrain, enhancing driver control and safety—a key feature of the FOX Disc Brake Axle (9 ton) With Leaf Spring (100 mm).

3. Optimal Braking Consistency

The disc brake setup on the FOX axle provides quick heat recovery and superior modulation. This is particularly important for trailers running close to the 9-ton limit, ensuring the braking distance remains predictable and consistent across various operating temperatures and prolonged usage cycles.

Proper Usage and Installation of the FOX Disc Brake Axle (9 ton) With Leaf Spring (100 mm)

To achieve the expected performance and reliability of this specialized assembly, installation must adhere strictly to technical standards.

1. Frame Preparation and Alignment

- Mounting Brackets: Ensure that the spring hangers and equalizer brackets are welded or bolted securely to the trailer frame, with absolute precision regarding their relationship to the trailer’s center line. Misalignment will cause excessive tire scrub and potential structural fatigue on the FOX Disc Brake Axle (9 ton) With Leaf Spring (100 mm).

- Spring Placement: The 100 mm leaf springs must sit flush on the axle seats. Use appropriate U-bolt kits designed to accommodate the 100 mm width for a tight and secure clamping force.

2. U-Bolt Torque Specifications

- Critical Step: Due to the specialized engineering of the FOX axle and the demands of the 9-ton load, U-bolt torque is non-negotiable. Always refer to the Chichest technical manual for the precise Newton-meter (Nm) or foot-pound (ft-lb) specification. Incorrect torque is the leading cause of axle shift and spring failure.

- Re-Torquing: After the first 500 kilometers of use, the U-bolts securing the FOX Disc Brake Axle (9 ton) With Leaf Spring (100 mm) must be re-torqued as the springs and components settle.

3. Brake Line Integration

For the disc brake system, whether hydraulic or air-over-hydraulic, all line connections must be robust, leak-free, and routed to prevent snagging or abrasive contact with moving parts.

- Bleeding Process: Thoroughly bleed the brake system according to manufacturer protocols to ensure zero air presence, guaranteeing immediate and full braking pressure at the caliper of the FOX Disc Brake Axle (9 ton) With Leaf Spring (100 mm).

How to Maintain Your FOX Disc Brake Axle (9 ton)

Maintenance for the FOX unit focuses on preserving the integrity of its precision components and maximizing the life of the 100 mm suspension system.

1. Bearing Service Intervals

- Premium Bearings: FOX axles utilize high-quality bearings, but their service life is directly proportional to grease quality and maintenance frequency. Under normal conditions for a 9-ton rated trailer, bearings should be inspected, cleaned, and repacked with approved, high-temperature axle grease at least once a year.

- Seal Integrity: Always replace the grease seal when repacking the bearings. A failed seal is the quickest way to contaminate the bearings of the FOX Disc Brake Axle (9 ton) With Leaf Spring (100 mm) with water and dirt, leading to premature failure.

2. 100 mm Leaf Spring Inspection

- Visual Check: Inspect the entire 100 mm leaf spring pack for broken leaves, especially near the center bolt and the shackle eyes.

- Bushings and Shackles: The rubber or bronze bushings in the spring eyes should be checked for excessive play. Worn bushings can cause clunking sounds, affect alignment, and reduce the effectiveness of the suspension. Tighten or replace worn shackles and bolts immediately.

3. Disc Rotor and Pad Monitoring

- Rotor Runout: Check the disc rotors for warping or excessive runout. Even minor warping can cause noticeable vibration and rapid, uneven pad wear on the FOX Disc Brake Axle (9 ton) With Leaf Spring (100 mm).

- Pad Replacement: Monitor the brake pads closely. Using specialized FOX components (or approved equivalents) ensures proper fit, friction characteristics, and warranty compliance. Replace pads when they reach 3 mm thickness.

Final Thought

The FOX Disc Brake Axle (9 ton) With Leaf Spring (100 mm) represents the pinnacle of heavy-duty trailer technology. By investing in this component, you are securing a foundation that is engineered for strength, optimized for safety, and built for longevity. Chichest is your trusted partner in providing the highest quality FOX axles, ensuring your operations never fall short of excellence.

Faq

-

What is the benefit of the FOX engineering over standard 9-ton axles?

The FOX engineering focuses on precision and material quality. This translates to tighter tolerances, more durable spindle ends, and better surface finishes, which ultimately reduce component drag, increase fuel efficiency, and ensure a longer, more reliable service life for the FOX Disc Brake Axle (9 ton) With Leaf Spring (100 mm) assembly.

-

Is a 100 mm leaf spring standard for a 9-ton axle?

While narrower springs are sometimes used, the 100 mm width is considered the premium, heavy-duty specification for this load class. It offers enhanced stability, better load sharing between the leaves, and is preferred in applications where trailer sway control is critical.

-

How do I ensure I purchase the correct brake rotor size for my FOX axle?

The brake rotor must perfectly match the FOX caliper bracket and wheel size. Always reference the Chichest part numbers and the specific model code of your FOX Disc Brake Axle (9 ton) With Leaf Spring (100 mm) when ordering replacement parts to guarantee compatibility and peak braking performance.

en

en fa

fa

ru

ru

There are no reviews yet.