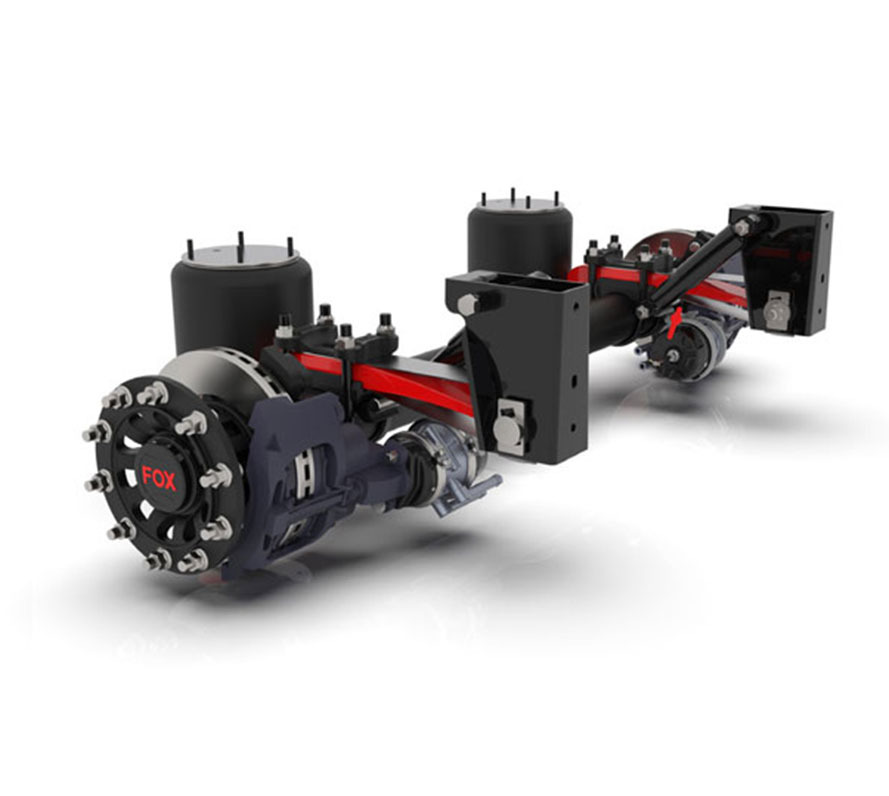

Disc Brake Axle with Leaf Spring (9 Ton): Unmatched Performance and Safety for Heavy-Duty Transport

In the demanding world of heavy-duty transportation and trailer manufacturing, the reliability of foundational components is non-negotiable. Among these critical parts, the Disc Brake Axle with Leaf Spring (9 ton) stands out as a paramount choice for ensuring both maximum payload handling and superior stopping power. Chichest proudly offers this robust solution, specifically engineered for the 9-ton capacity range, delivering a perfect blend of high structural integrity and advanced braking technology.

This comprehensive guide delves into why the Disc Brake Axle with Leaf Spring (9 ton) is the preferred choice for commercial, agricultural, and industrial trailers, outlining its key features, operational benefits, proper usage, and essential maintenance practices. By integrating a high-performance disc brake system with the time-tested efficiency of leaf springs, this assembly provides a safer, more stable, and more durable foundation for your heaviest loads.

Advantages of Using the Disc Brake Axle with Leaf Spring (9 Ton)

The integration of disc brakes onto a heavy-duty 9-ton axle supported by leaf springs offers a synergistic array of benefits that directly impact operational efficiency, safety, and longevity.

1. Superior Braking Performance (The Disc Brake Edge)

Unlike traditional drum brake systems, the disc brake component on this 9-ton axle provides:

- Exceptional Heat Dissipation: Disc brakes shed heat much faster, drastically reducing the risk of brake fade during long descents or continuous heavy use. This ensures consistent and reliable stopping power when you need it most.

- Wider Stopping Range: They offer a more responsive and linear braking feel, crucial for controlling a fully loaded trailer. This translates to shorter stopping distances and enhanced road safety.

- Self-Adjustment: Disc brakes typically require less maintenance related to adjustment, as they are inherently self-adjusting, simplifying the operational upkeep of the Disc Brake Axle with Leaf Spring (9 ton).

2. Enhanced Durability and Load Distribution (The Leaf Spring Integration)

The leaf spring suspension component is celebrated for its simplicity and strength, making it ideal for the 9-ton weight class:

- Robust Load Bearing: Leaf springs are inherently strong and excellent at carrying heavy vertical loads, providing reliable support for the full 9-ton capacity.

- Effective Shock Absorption: They effectively dampen road shocks, protecting both the trailer structure and the cargo from excessive vibration and stress.

- Simplified Design: The straightforward design of the leaf spring suspension makes the entire Disc Brake Axle with Leaf Spring (9 ton) assembly rugged, reliable, and easier to maintain compared to complex air or hydraulic systems.

3. Optimized Safety and Compliance

- Improved Stability: The structure of the leaf spring system helps maintain axle alignment and lateral stability, crucial for high-speed towing of heavy trailers.

- Reduced Maintenance Costs: While the initial cost might be higher, the superior durability of the braking components and the robust nature of the axle lead to fewer breakdowns and lower long-term maintenance expenditures.

How to Use and Install the Disc Brake Axle with Leaf Spring (9 Ton)

Proper installation and alignment are crucial to harness the full potential and safety benefits of the Disc Brake Axle with Leaf Spring (9 ton). We strongly recommend professional installation, but here are the key steps involved:

1. Pre-Installation Check

- Verify Capacity: Ensure the Gross Axle Weight Rating (GAWR) of the axle (9 tons / 9,000 kg) matches or exceeds your trailer’s design requirements.

- Component Inspection: Check all brake pads, rotors, caliper mounts, and leaf spring components for any shipping damage or defects.

2. Installation of Leaf Springs

The leaf springs must be securely mounted to the trailer frame using robust hangers and shackles. The spring seats on the axle tube must align perfectly with the springs to prevent spring shifting under load.

3. Axle and Brake Line Connection

The Disc Brake Axle with Leaf Spring (9 ton) is then mounted onto the springs. U-bolts must be torqued to the manufacturer’s specifications to ensure a secure, non-slip connection.

- Brake Line Plumbing: Connect the brake calipers to the trailer’s hydraulic or air braking system (depending on the specific disc brake model). All lines must be secured and protected from road debris. Bleed the brake lines thoroughly to remove all air and ensure maximum hydraulic efficiency.

4. Post-Installation Alignment and Testing

- Axle Alignment: Crucially, the axle must be aligned perpendicular to the trailer frame and parallel to any other axles. Misalignment will cause tire wear and affect handling.

- Brake Adjustment & Bedding: Perform initial brake adjustments (if applicable) and follow a proper "bedding-in" procedure (a series of moderate and firm stops) to optimize the friction surface between the pads and rotors of the Disc Brake Axle with Leaf Spring (9 ton).

How to Maintain the Disc Brake Axle with Leaf Spring (9 Ton)

Regular, proactive maintenance significantly extends the lifespan of your 9-ton axle assembly and ensures continued safety and compliance.

1. Routine Brake System Checks

- Pad and Rotor Wear: Inspect the disc brake pads for uniform wear and measure the rotor thickness. Replace pads before they reach minimum thickness to prevent rotor damage.

- Hydraulic/Air Lines: Check all brake lines, hoses, and connections for leaks, chafing, or corrosion. The braking system is the primary safety feature of the Disc Brake Axle with Leaf Spring (9 ton).

- Caliper Function: Ensure the brake calipers are sliding freely and not seizing. A seized caliper can cause excessive heat and premature pad wear.

2. Suspension and Bearing Maintenance

- Leaf Spring Inspection: Check the leaf springs, shackles, and hangers for cracks, stress points, or excessive rust. Ensure all bolts are tight and that bushings are not worn out.

- Axle Bearings: Check and repack the wheel bearings annually (or as per manufacturer guidelines) with high-temperature grease. Proper bearing maintenance is vital for preventing catastrophic axle failure under the 9-ton load.

- Tire Inspection: Regularly monitor tire pressure and check for abnormal wear patterns, which can indicate an alignment issue with the Disc Brake Axle with Leaf Spring (9 ton).

3. General Cleaning and Protection

Keep the axle assembly, particularly the brake area, free from heavy buildup of dirt, salt, and grime, which can accelerate corrosion and wear. Touch up any paint damage on the axle tube to prevent rust from compromising the structural integrity of the Disc Brake Axle with Leaf Spring (9 ton).

Final Thought

The Disc Brake Axle with Leaf Spring (9 ton) is more than just a component; it is an investment in the safety, efficiency, and longevity of your heavy-duty fleet. By prioritizing superior stopping power and the rugged reliability of leaf springs, Chichest ensures that your equipment can handle the toughest loads and environments with confidence. Proper installation and adherence to the recommended maintenance schedule will ensure that your 9-ton axle delivers peak performance for years to come.

Faq

-

Why should I choose a disc brake axle over a drum brake axle for a 9-ton trailer?

Disc brakes offer vastly superior heat dissipation, making them less prone to brake fade under heavy load (9 tons) and continuous use. They also provide more reliable, consistent, and easier-to-maintain braking performance compared to drum systems. This directly enhances the overall safety and stopping distance of your Disc Brake Axle with Leaf Spring (9 ton) equipped trailer.

-

Is the 9-ton capacity rated per axle or for the entire trailer?

The 9-ton (or 9,000 kg) capacity is the Gross Axle Weight Rating (GAWR) for one single axle. For a tandem axle trailer, the total carrying capacity of the suspension would be 18 tons (plus the tongue weight). Always ensure your trailer frame and components are rated for the combined capacity of your Chichest axles.

-

Can I convert my existing 9-ton drum brake axle to a disc brake system?

While it is technically possible in some cases, it often requires significant modifications, including the replacement of the hub assembly and potentially the spindle end. It is generally safer, more reliable, and often more cost-effective to replace the entire assembly with a purpose-built Disc Brake Axle with Leaf Spring (9 ton) unit from a trusted supplier like Chichest.

en

en fa

fa

ru

ru

There are no reviews yet.